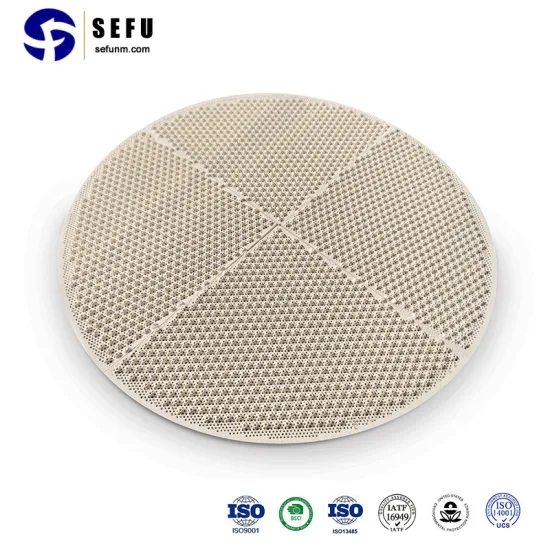

Far Infrared Air Ceramic Sheet Heater Element Plate

Far infrared heating plate is also called the far infrared heater, the far infrared heater, is a kind of heating plate.

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | sheet |

| Application | Thermoforming |

| Shape | Flat,Hollow |

| Machinery Test Report | Provided |

| Warranty of Core Components | 1 Year |

| LED Wire | 250mm |

| Working Temperature Range | -5 - 700 ºC |

| Use | Plastic Injection Molding |

| Insulation Material | 95% Al2O3 Ceramic |

| Dimension(L*W*H) | 240 X 60, 240 X 80 |

| Condition | New |

| Material | Ceramic |

| Voltage | 48V/110V/220/230/240/380/480 |

| Power | 100-2500W |

| Sample | Free Sample, Customer Take Shipping Cost |

| Video Outgoing-Inspection | Provided |

| Transport Package | Foam /Carton |

| Specification | 240 x 60, 240 x 80, 122 x 122, 122 x 60, 60 x 60 |

| Trademark | shenglongpan |

| Origin | Jiangsu |

| HS Code | 8514400090 |

| Production Capacity | 500000/Month |

Product Description

Far infrared heating plate is also called the far infrared heater, the far infrared heater, is a kind of heating plate.

The energy saving of far infrared heater is formed by curing coating on the radiant surface of the heater. The coating can absorb a lot of radiant heat energy, and because of its high emissivity, it can convert the absorbed radiation heat energy into the far infrared thermal energy that is easy to be absorbed in the form of electromagnetic wave. Micron electric coating coating thickness, heat resistance, high reflectivity, used for oven board surface, the loss of heat energy into far infrared heat in the form of electromagnetic wave radiation oven, for the oven, and not easy to be absorbed by moisture absorption, thus the heat energy in the oven, not only reduces the damp temperature, and make the temperature in the oven, make the temperature in the oven is fully utilized. Nano scale electric thermal coating of thin, small thermal resistance, used in the oven thermal temperature of metal material surface, in the process of heat transfer, the coating layer will not only absorb radiation heat energy into far infrared heat transfer, its itself into far infrared radiation heat source, but also because of the improvement of the surface temperature, temperature gradient increase, make the heated object heat conduction strength, heat absorption capacity is improved greatly. In short, the direct effect of converting the radiant heat energy into the far infrared thermal energy is: improve the temperature of the oven, reduce the temperature of the moisture discharge loss, enhance the heat energy absorption speed of the heated object; reduce the heat energy loss, to achieve the purpose of energy saving.

Product Description

110v 120v 220v 230v 240v Far Infrared Ceramic Heater for Thermoforming operate in the temperature of 300°C to 700°C (572°F - 1292°F) producing infrared wavelengths in the 2 - 10 micron range. Most plastics and many other materials absorb infrared best in this range, which makes the ceramic heater the most popular infrared radiant emitter on the market. A range of aluminised steel reflectors are also available to ensure the maximum amount of infrared radiation is reflected forward to the target area.| Product Name | 110v 120v 220v 230v 240v Far Infrared Ceramic Heater for Thermoforming |

| Color | white, yellow, black, etc |

| Power | 125-1500W |

| Usually size | 245 x 60, 245 x 80, 122 x 122, 122 x 60, 80 x 80,60 x 60mm |

| Shapes | Trough, Hollow and Flat |

| Voltage | 110-440volts |

| Thermocouple | Optional, K or J Type |

| Operating Temperature | 300C - 700C |

FAQ1. Q: Are you factory or trading company? A: Yes, we are factory and have 8 production lines.2. Q: Can we use our own forwarder to transport the products?

A: Yes, sure. We can ship to them.3. Q: Can we print our own brand?

A: Yes, of course. Will be our pleasure to be one your good OEM manufacture in China to meet your requirements.4. Q: What's the payment method?

A: T/T, 30% deposit before production, the balance before delivery.Also, we accept go through on alibaba, west union.5. Q: How to place an order?

A: Please kindly send us your order by email, we will confirm the PI with you. We wish to get your email address, phone number,destination, transportation way. And product information, size, quantity, logo, etc.Anyway, please contact us directly by email or online message.

Related Products

-

![Car Door Window Rubber Composite Seal Strip U Shape EPDM Rubber Sealing Strip]()

Car Door Window Rubber Composite Seal Strip U Shape EPDM Rubber Sealing Strip

-

![Custom Size Soft Gasket Door Weatherstrip Silicone Rubber Car Sealing Strip]()

Custom Size Soft Gasket Door Weatherstrip Silicone Rubber Car Sealing Strip

-

![Siny High Quality Cotton More Specifications Kinematics Medical Supply Waterproof Athletes Kinesiology Tape]()

Siny High Quality Cotton More Specifications Kinematics Medical Supply Waterproof Athletes Kinesiology Tape

-

![Siny More Specifications Cotton Kinematics Medical Supply Waterproof Athletes Muscle Sports Tape OEM]()

Siny More Specifications Cotton Kinematics Medical Supply Waterproof Athletes Muscle Sports Tape OEM